commit 7ec954addaee7b12c93520ab31b37e72c6ff69d4

parent a6f143e16da19f01d0b1d60f5d03e88ec7d715a3

Author: Samdal <samdal@protonmail.com>

Date: Fri, 28 Feb 2025 20:08:32 +0100

soldering tutorial

Diffstat:

11 files changed, 80 insertions(+), 0 deletions(-)

diff --git a/_posts/2025-02-28-soldering-tutorial.md b/_posts/2025-02-28-soldering-tutorial.md

@@ -0,0 +1,80 @@

+---

+layout: post

+title: "How to Solder [Quick Tutorial]"

+description: Quick simple soldering tutorial

+comments: true

+tags: [writing, tutorial, electroincs]

+---

+

+## 1. Equipment

+

+

+### Essential Equipment

+

+

+\

+Soldering Iron\

+Solder

+{: style="text-align: center;"}

+

+*(A temperature-controlled soldering station is better, but the non-regulated ones work fine)*

+{: style="text-align: center;"}

+

+### Recommended Equipment

+

+

+\

+Tweezers\

+No-clean Flux\

+Solder Sucker\

+Solder Wick\

+Helping Hands

+{: style="text-align: center;"}

+

+

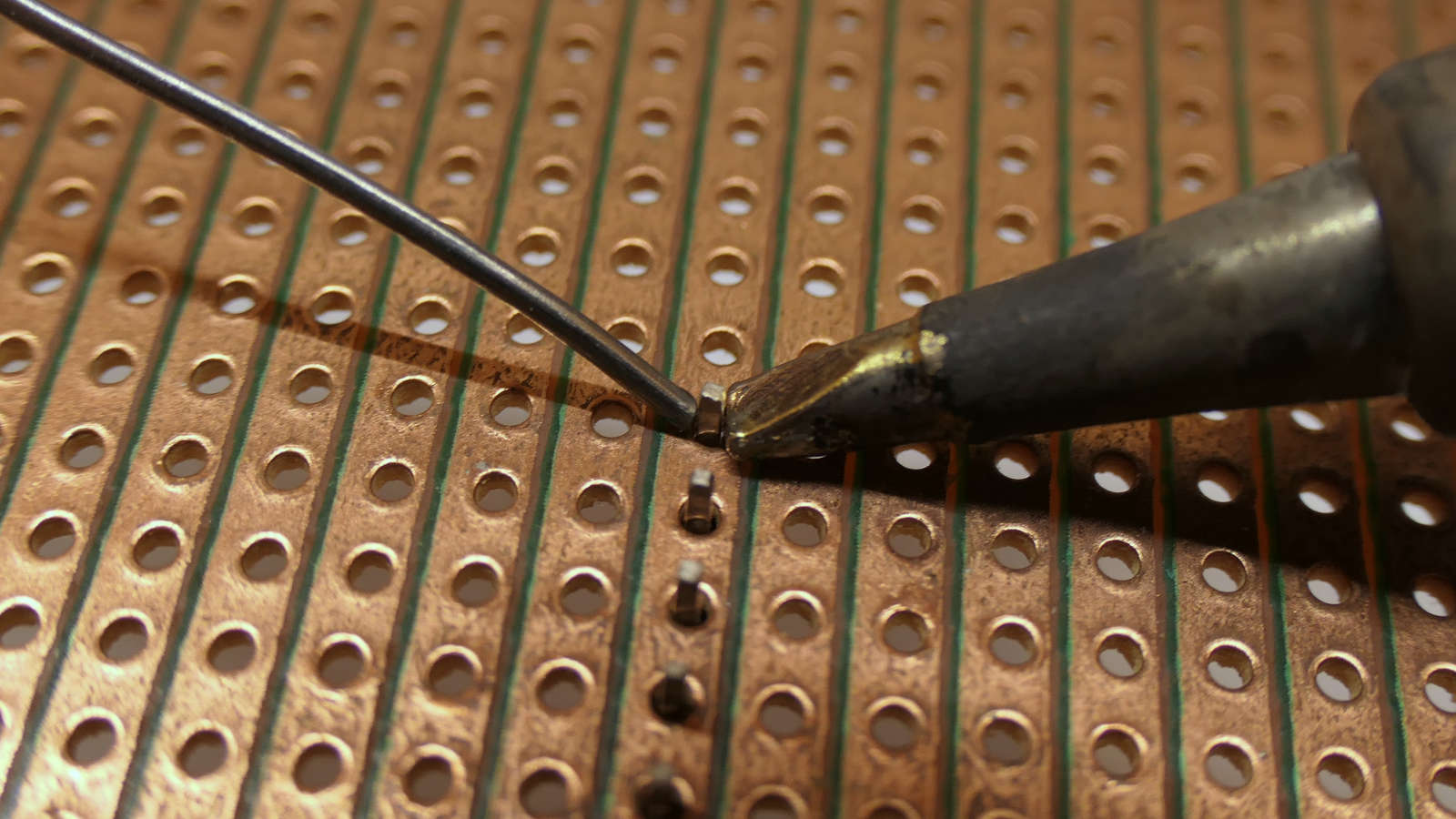

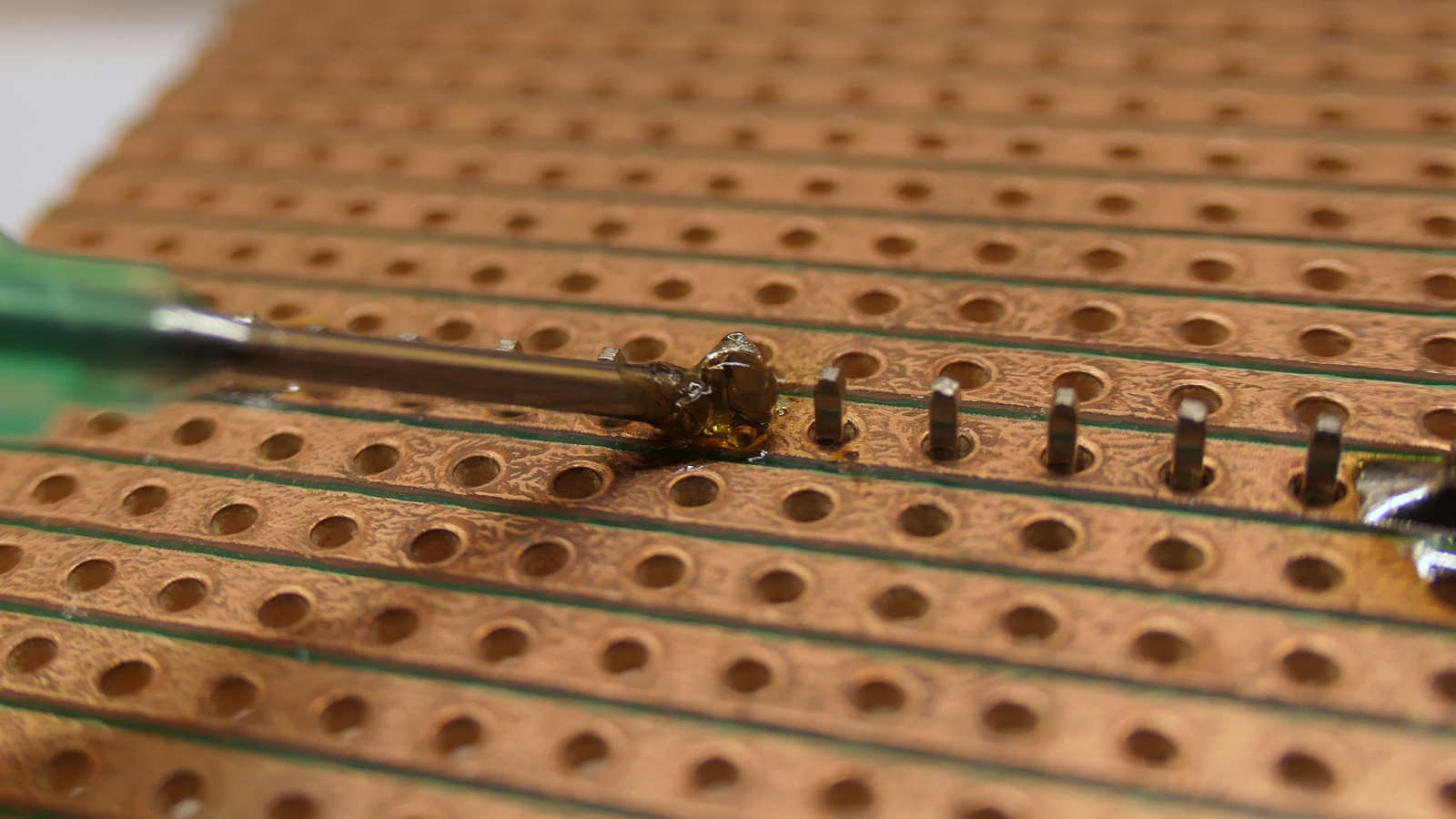

+## 2. Don't put solder on the iron itself

+

+**Flux is essential for soldering**. It cleans up surface oxide. Without it, your solder joints will be terrible.

+The solder has flux inside it. Putting it on the iron itself makes the flux evaporate.

+To avoid this, heat the joint from one angle and apply the solder from another.

+

+

+{: style="text-align: center;"}

+

+

+

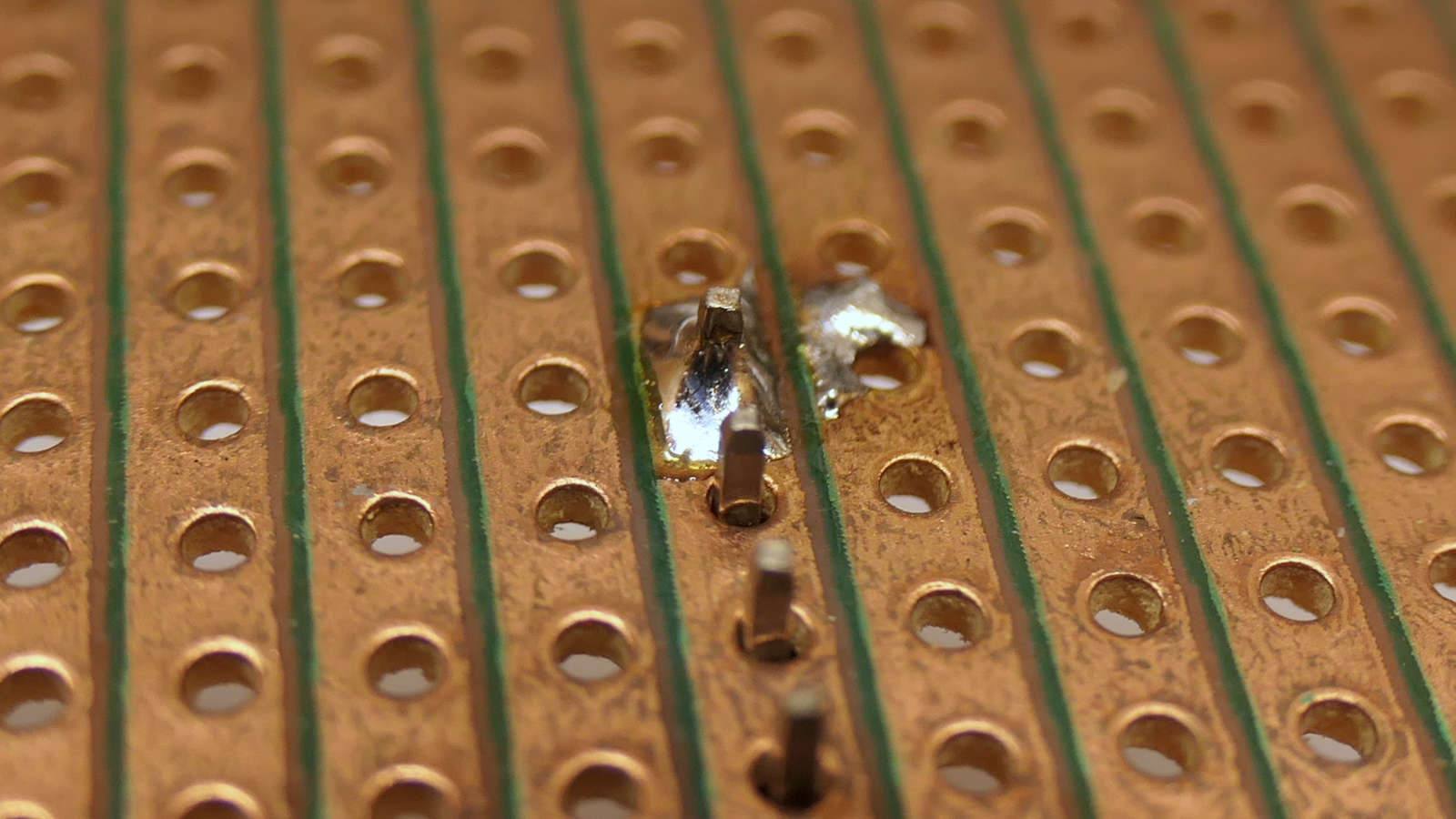

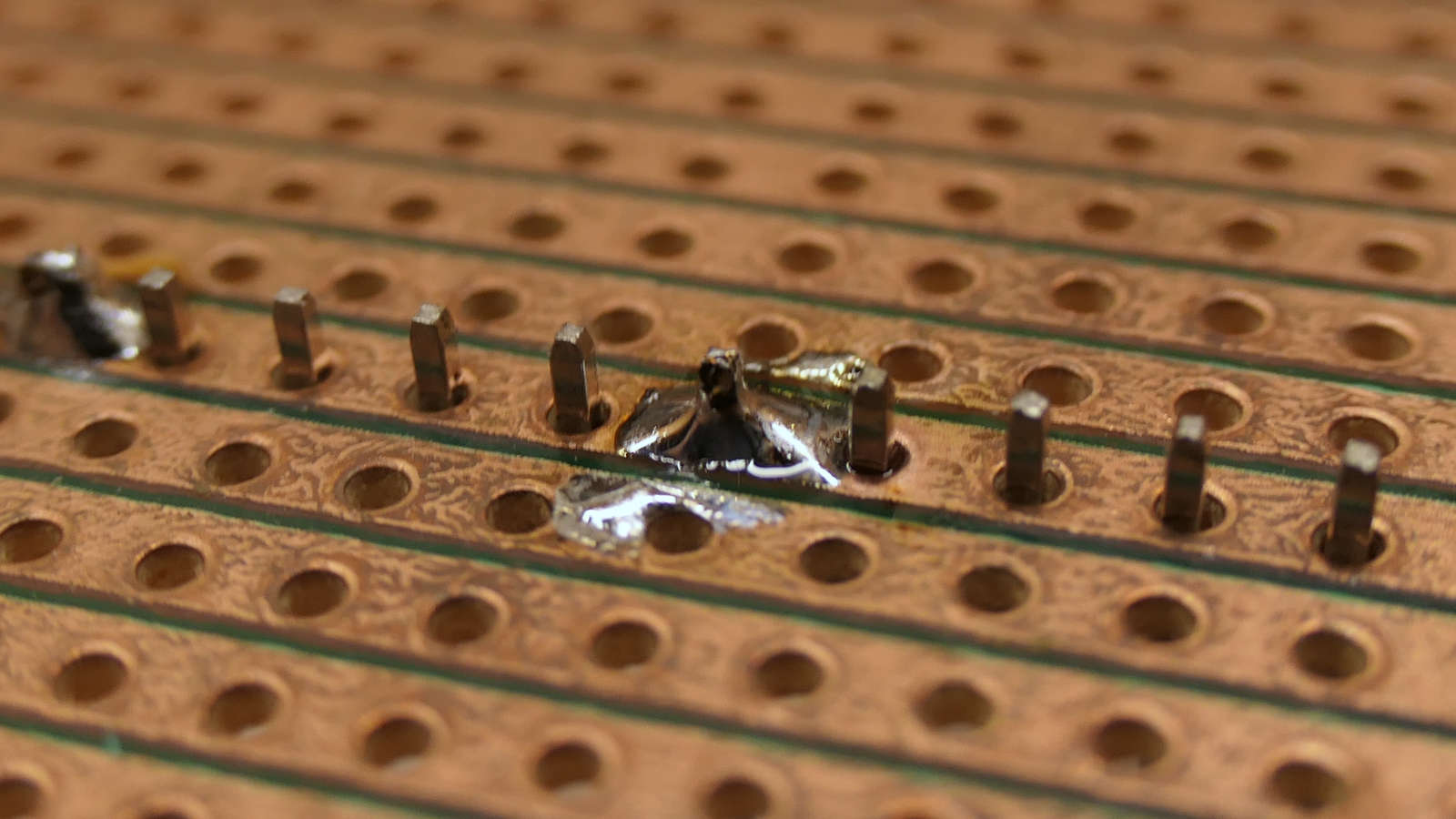

+{: style="text-align: center;"}

+

+Look, it's a perfect joint!

+

+Occasionally, it's hard or impossible to apply solder on the joint separately. In that case, you need to supply the joint with extra flux, either with external flux or touching up the joint again later.

+

+If you have trouble heating the joint, apply a tiny amount of solder to the iron to help transfer heat. The liquid solder will increase the surface area and bond the iron and the joint.

+

+

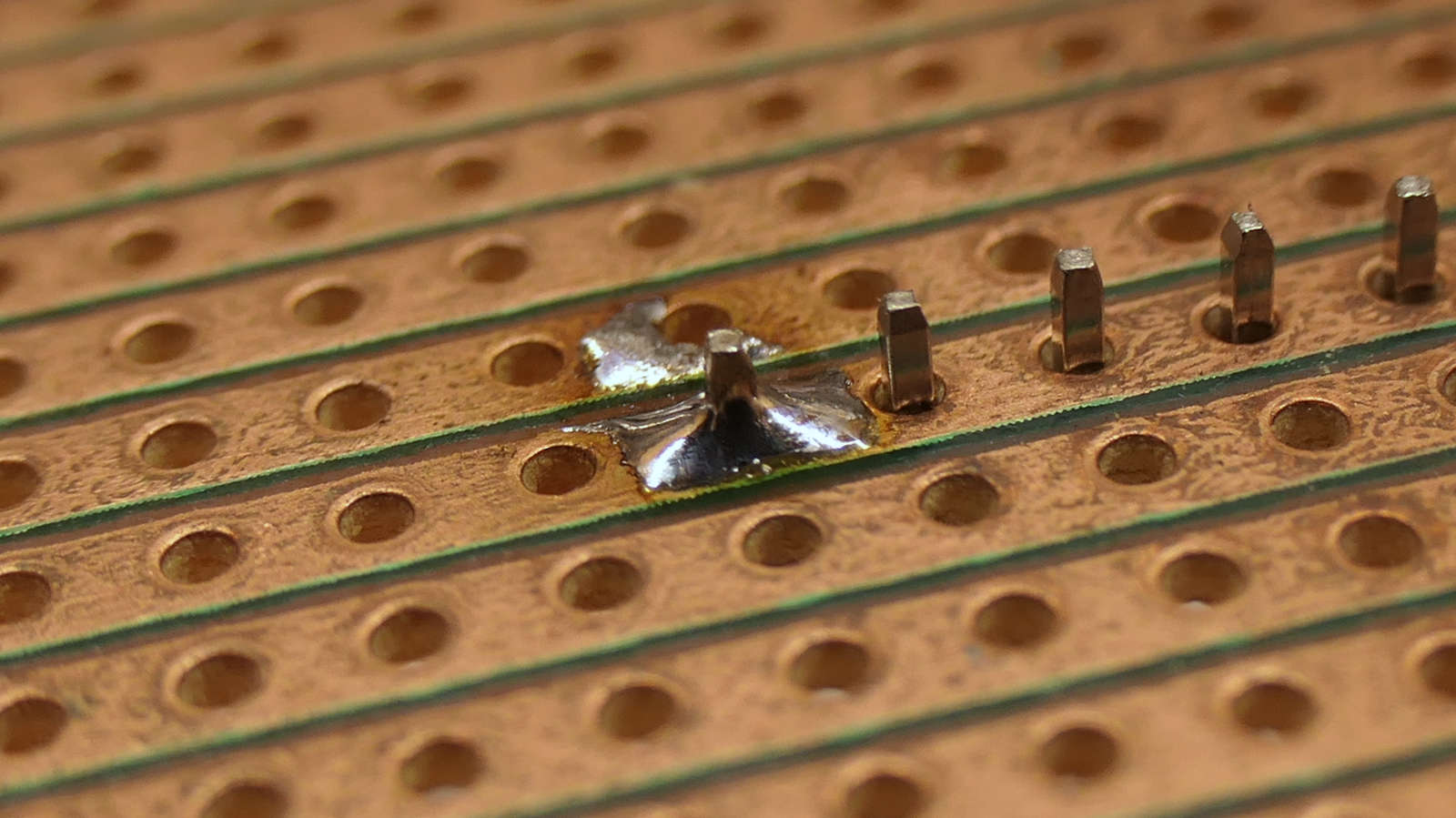

+## 3. Use plenty of flux

+

+You usually get away with only the flux in the solder for through-hole components. With surface-mount components, having external flux makes a daunting task become a breeze.

+Even so, don't be afraid of using flux on through-hole devices. It helps improve bad and tricky junctions.

+

+

+

+

+{: style="text-align: center;"}

+

+

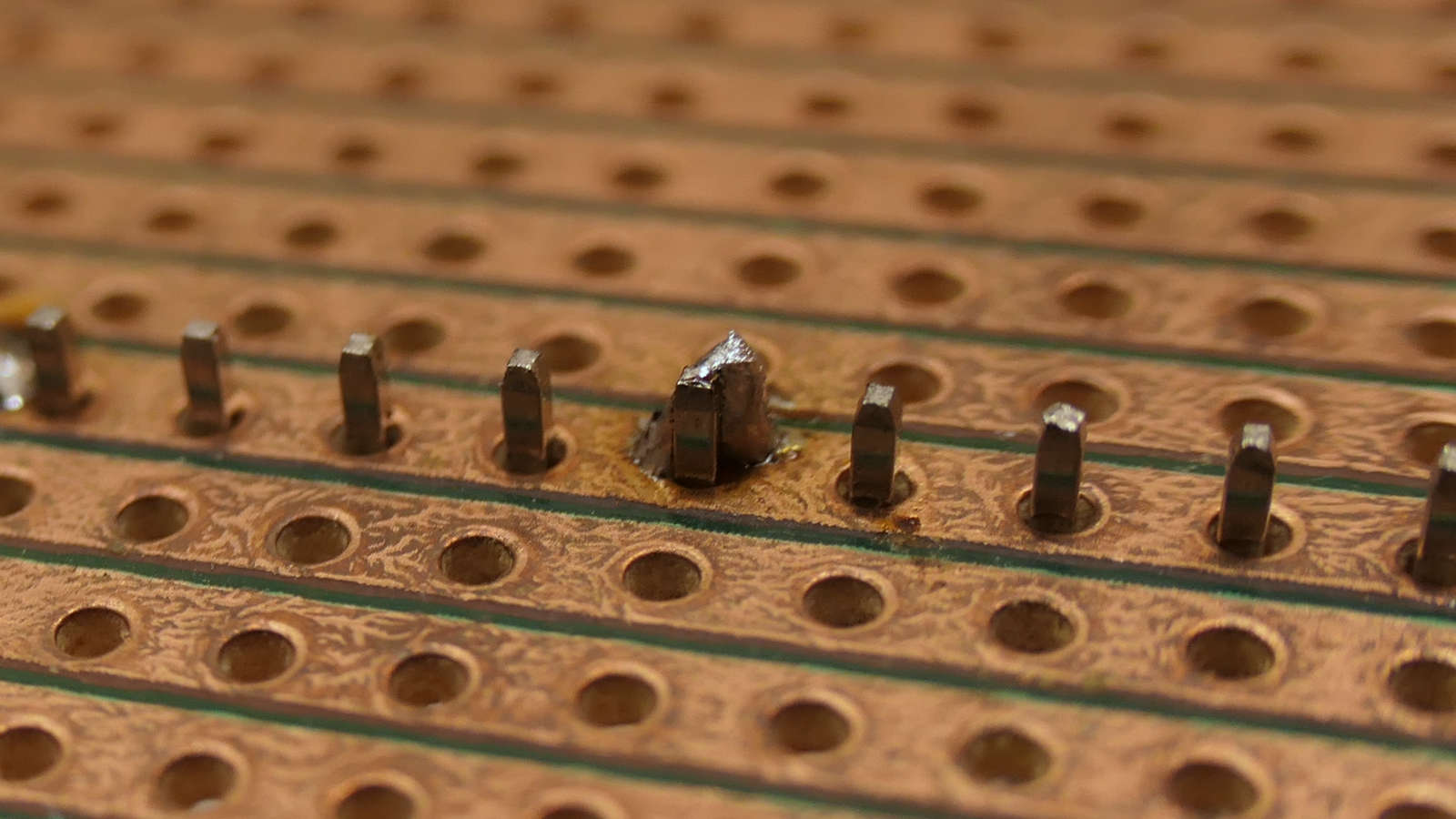

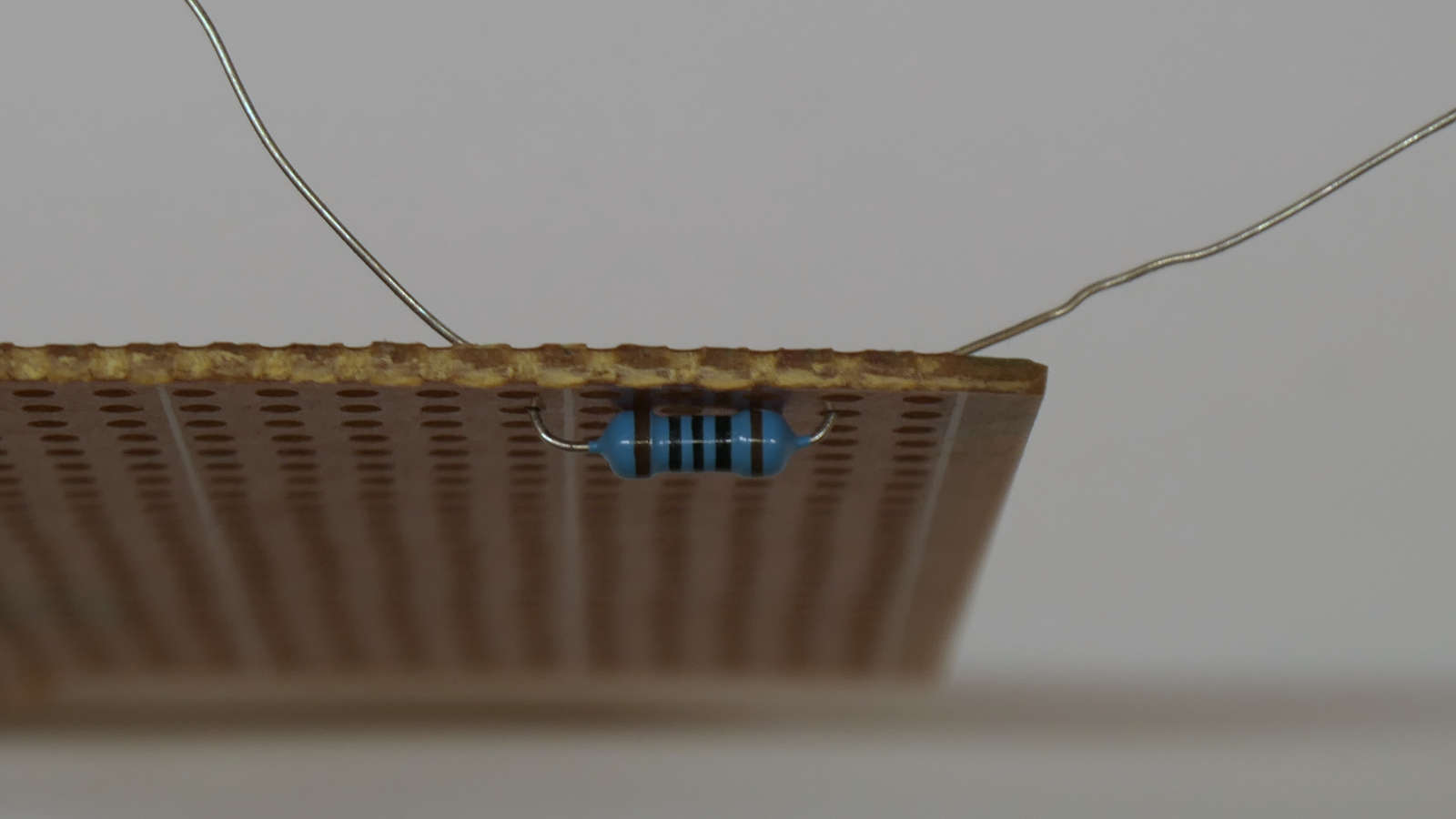

+## 4. Extra tips

+

+- Assemble smaller components first. Doing so makes components more accessible and easier to hold in place.

+- Bending the leads on through-hole components makes the friction hold them in place.

+

+

+{: style="text-align: center;"}

+

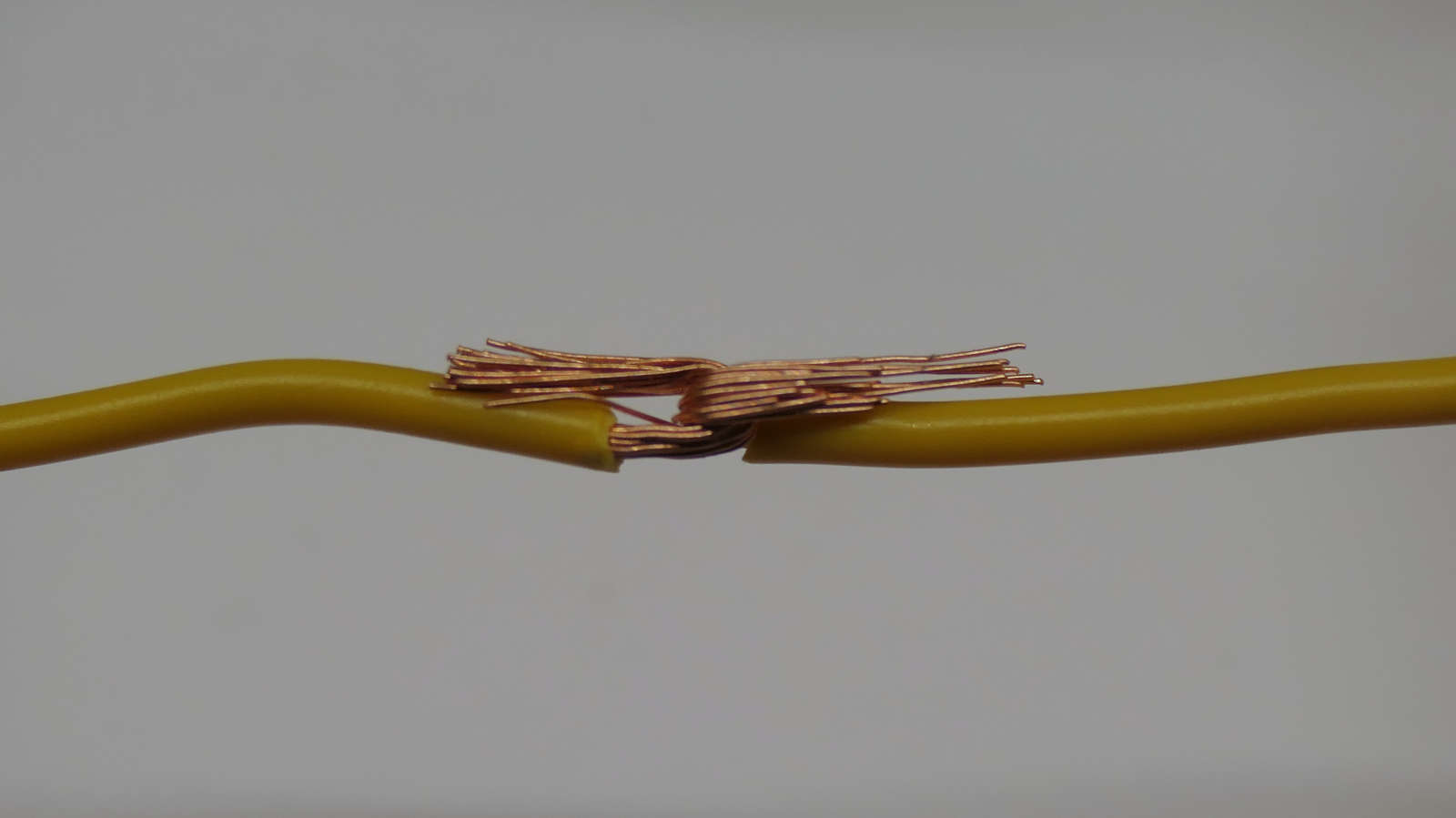

+- Joining two wires through a mechanical connection will make it stronger and easier to solder.

+

+

+{: style="text-align: center;"}

+

+- When doing surface-mount components, it can be beneficial to poorly attach one or two legs of the IC. You can fix them later.

+- Isopropyl alcohol is good at cleaning flux residue.

diff --git a/assets/images/soldering_tutorial/essentials.jpeg b/assets/images/soldering_tutorial/essentials.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/recommended.jpeg b/assets/images/soldering_tutorial/recommended.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder1.jpeg b/assets/images/soldering_tutorial/solder1.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder2.jpeg b/assets/images/soldering_tutorial/solder2.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder3.jpeg b/assets/images/soldering_tutorial/solder3.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder4.jpeg b/assets/images/soldering_tutorial/solder4.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder5.jpeg b/assets/images/soldering_tutorial/solder5.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder6.jpeg b/assets/images/soldering_tutorial/solder6.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder7.jpeg b/assets/images/soldering_tutorial/solder7.jpeg

Binary files differ.

diff --git a/assets/images/soldering_tutorial/solder8.jpeg b/assets/images/soldering_tutorial/solder8.jpeg

Binary files differ.